UNDER CONSTRUCTION

R-Value

Green Roof

Green Roof Gardens... Click to open

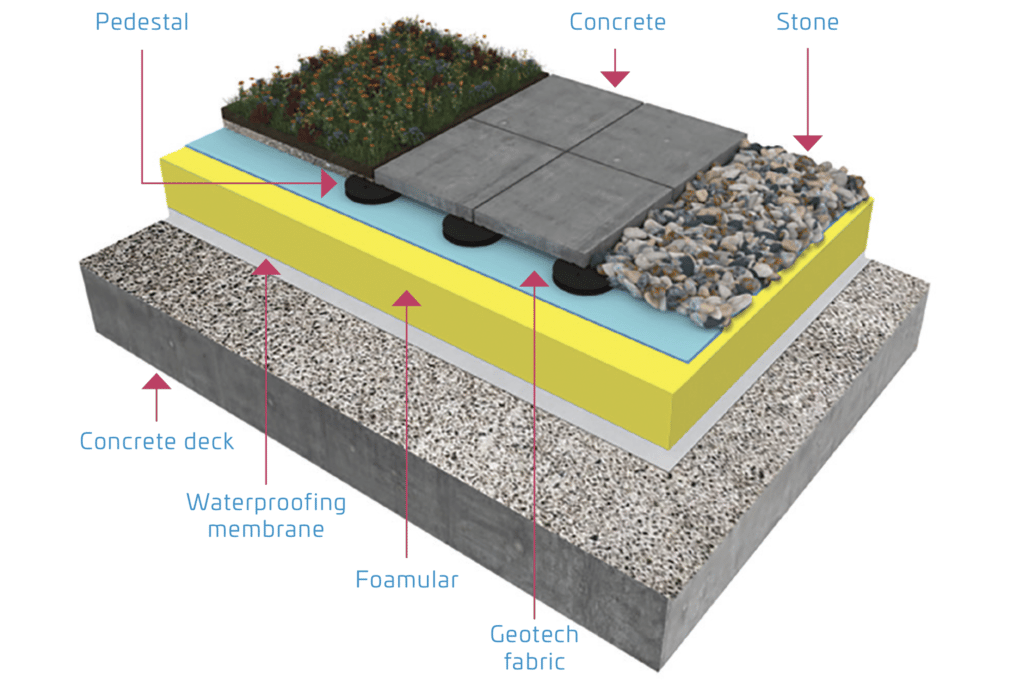

Green Roof Gardens are becoming an increasingly popular roofing option for concrete roofs, with many modern cities demanding a percentage of total roof space be green. Green Roof Gardens reduce surrounding temperatures, provide insulation, improve air quality, reduce storm water runoff and provide people and animals with more outside space. Green Garden Roofs will provide some insulation from the soil and plants, but for adequate R-values, added insulation is needed. Extruded Polystyrene is a closed cell board with minimal water absorption and high R-values. It is placed below the soil but above the concrete roof, creating a continuous thermal barrier. It can also have pavers and ballast placed on it, providing walkways and recreation areas.

Extruded Polystyrene provides no nutritional value to plants, animals or bacteria, so it is not degraded by their presence. It also has very low water absorption potential, and can easily function in the presence of moist growing medium and water runoff. Extruded Polystyrene's high compressive strengths means it is not affected by continuous pressure from foot traffic, growing medium or other loads. Austech has a range of compressive strengths available that can deal with heavy loads, including vehicular traffic.

"Green Roof Gardens Are Carbon Sequestrators, Absorbing Carbon From The Air & Improving Air Quality"

PRMA

Protected Roof ...Click to open

Protected Roof Membrane Assembly (PRMA) is a simple and effective method concrete roof insulation method while also protecting the waterproof membrane. Foamular Extruded Polystyrene Insulation is placed directly over the waterproof membrane, providing protection for the membrane, but also creating a continuous thermal barrier on the roof. Foamular is held in place with a specified ballast, usually gravel or concrete pavers.

Cold Storage

Cold storage... Click to open

Cold storage is one of the most extreme environments insulation can be exposed to. There is extreme cold, massive amounts of moisture from condensation, plus floor insulation has to cope with extreme pressure from vehicles and stored products.

Foamular Extruded Polystyrene Insulation has been used extensively in cold storage insulation, from small supermarket cool rooms to huge commercial storage facilities, like the 28,000m² Rand Cold Storage Distribution Centre. When used in cold storage applications, Foamular routinely outperforms most other insulation products in maintaining insulation performance and supporting the imposed load.

Commercial & Residential

Commercial and... Click to open

Commercial and residential Underslab Insulation Concrete possesses very poor thermal properties but it is essential for modern large-scale construction. Foamular has been successfully used to insulate under commercial concrete slabs, creating an efficient thermal barrier that reduces temperature fluctuations and improves energy efficiency. "Fire Resistant Insulation Saves Energy and Lives" Foamular's high R-values create greater thermal efficiency, but it also provides greater R-values in smaller thicknesses, so it takes up less space once installed than other boards. This is especially important in retrofitting applications where insulation will reduce head-high.

Concrete possesses very poor thermal properties but it is essential for modern large-scale construction. Foamular has been successfully used to insulate under commercial concrete slabs, creating an efficient thermal barrier that reduces temperature fluctuations and improves energy efficiency. "Fire Resistant Insulation Saves Energy and Lives" Foamular's high R-values create greater thermal efficiency, but it also provides greater R-values in smaller thicknesses, so it takes up less space once installed than other boards.

Foamular can be fixed in a variety of methods, including Hiltie XIE, Ramset Systems and furring channels. Foamular has a high tensile strength of 300KPA, so it can even be fixed with approved adhesive. All Foamular products are guaranteed to maintain 90% minimal thermal performance for a period of 20 years. This makes Foamular an investment that can pay for itself in energy savings.

Wine Cellar Insulation

Wine cellar... Click to open

Wine cellar insulation successful wine storage requires constant temperature and high humidity, creating some unique problems for insulation. Most insulation would under perform in these conditions, but Foamular is not affected by moisture in the air, so it is ideal for this unique circumstance. Serious wine storage requires expensive temperature and humidity control, but Extruded polystyrene's high R-values create an effective barrier to temperature fluctuations, reducing the strain on machines and improving energy efficiency.

Extruded Polystyrene can be directly fixed to timber, steel, masonry or concrete. Extruded Polystyrene will not aid in the transfer of humidity, which helps protect the adjoining rooms and structures. Foamular is also an ideal substrate for many finishing systems, including render, timber and stone. Extruded Polystyrene is closes cell insulation, so it minimises potential water absorption. This is vital, since water absorption reduces insulation's thermal abilities. Foamular Extruded Polystyrene Insulation requires no additional waterproofing and can easily cope with regular water immersion, making it ideal for retrofitting on older buildings.

Concrete Sandwich Panels

Masonry and concrete... Click to open

Masonry and concrete offers quick and efficient construction, but very poor insulation performance. Extruded Polystyrene can be used to bridge the gap by sandwiching it and creating insulated panels, providing superior thermal properties and increasing the thermal value of external walls, while maintaining construction efficiencies. Typical concrete tilt wall panels must be insulated after casting and installation. Using Extruded Polystyrene insulation and connector ties, the panels are insulated during casting, prior to erection. Thus, the insulation is integral to the wall, which results in easier and faster construction. In addition, since the insulation is "sandwiched" between the structural concrete wythe and the fascia wythe, the insulated panels maintains hard, durable concrete surfaces, both inside and out.

Austech has a unique low conductivity wall tie system, manufactured from a high-performance, engineered thermoplastic resin. Unlike other insulated sandwich panel designs which rely on metal or solid concrete connections, the use of non-conductive connector ties minimizes the energy-draining effects of thermal bridging and results in insulated sandwich panels with maximum thermal performance and limited heat transfer. Just 50mm of Foamular has an R value of R1.78. In comparison, 110mm of brickwork achieves R0.18 and a 100mm concrete slab achieves just R0.069. Foamular is therefore the ideal solution to improve the performance of these walls and our insulated panels are ideal for BCA part J construction. If the insulated panel has two or more openings, or an opening is too close to the insulated panel edge, be sure that the space between them has at least two rows of ties.

Model Making

Model Making... Click to open

Model making foam Extruded Polystyrene has been used extensively for model making, including for model railways, model boats, surf boards, architectural modelling, sculptures, and table-top games such as Warhammer. Extruded Polystyrene sheets are 25mm to 100mm thick and can be cut and shaped into almost any shape or dimension. Boards can also be easily glued together with a Polystyrene-compatible adhesive to make thicknesses greater than 100mm.

Boards can be shaped into a variety of shapes using traditional woodworking tools to create realistic mountains, buildings, valleys, and scenery. Extruded Polystyrene is a closed-cell board with high rigidity, so even when carved it maintains its structural integrity. Once shaped boards can be painted or finished in a variety of manners. The lightweight nature of Foamular also makes it ideal for portable models or displays.

Floor Heating

On ground slabs... Click to open

On ground slabs with in-slab heating systems are a healthy and efficient way to heat a house. As the slab heats, the warmth rises through the house, heating the rooms and maintaining a constant temperature. Unfortunately, the cold ground the slabs sit on and cool air around it draw much of the heat out of the slab, so the system has to work harder and longer to maintain the temperatures, putting pressure on the system and dramatically increasing energy consumption. When placed under the slab and around the exposed perimeter, Foamular acts as a continuous thermal barrier, limiting temperature fluctuations, reducing energy demand and prolonging the life of the system. During Installation, Foamular is simply laid directly over the slab area, on top of the plastic sheeting, with supports and reinforcement placed over the Foamular, then the slab is laid on top. Any remaining exposed edges can be covered in Foamular encasing the slab in insulation.

As Foamular is not affected by moisture, soil borne bacteria or mould it can be back filled against for gardens etc, with no loss of thermal or physical properties. Foamular maintains its 20 year 90% thermal properties guarantee even when covered by concrete and dirt, giving you long term energy and environmental savings.

"Lower Energy Demand = Lower Operating Costs = Lower Greenhouse Gas Emissions"

Lightweight Construction

Masonry... Click to open

Rendered brick and masonry is becoming an increasingly popular exterior facade in all areas of construction, but it has poor thermal performance, is very labour intensive and is extremely heavy. Extruded Polystyrene is an ideal energy efficient substrate for EIFS, especially suited for the new generation PM render finishes. Foamular has high 'R' Values (50mm=R1.78) which are guaranteed not to drop below 90% of the original value for 20 years.

Foamular is fixed directly to the studs, providing a continuous thermal barrier around your home. Wall batts simply fill cavities, but the wooden studs act as an easy route for temperature fluctuations. Using extruded polystyrene as an external insulation is up to 30% more efficient than between stud insulation. Extruded Polystyrene with render is ideal for renovations and first floor extensions because it is extremely lightweight, reducing the need for structural support. Foamular is also much quicker to install and requires no drying time, so you can install the Foamular and render it in the same day! Foamular comes in varying thicknesses, from 25mmm up to 100mm, so you can match the thickness of brick or other substrates, helping your addition or extension blend into the existing structure.

"Foamular Minimises Thermal Bridging, Literally Wrapping Your Home In Insulation"

Stella RX

Stella RX insulation’s R-value is based on real-time ageing and the product is warranted to maintain 90% of its insulating value for twenty years. Stella RX insulation has a combination of characteristics that yield very low water absorption and is available in a range of compressive strengths that accept loads up to their design limit with little deformation.

Insulation performance you can trust

Stella RX insulation’s R-value is based on real-time ageing and the product is warranted to maintain 90% of its insulating value for twenty years. Stella RX insulation has a combination of characteristics that yield very low water absorption and is available in a range of compressive strengths that accept loads up to their design limit with little deformation.

FAQ - Frequently Asked Questions & Downloads

What is Stella RX?

Stella RX is a closed-cell extruded polystyrene insulation board.

What sort of projects can Stella RX be utilised on?

Stella RX has a range of applications, from insulating commercial roofs, also insulating under house slabs.

what is the difference between extruded and expanded polystyrene?

Expanded polystyrene (EPS) is beads of polystyrene expanded by steam into blocks that are then cut into boards. This process leaves air gaps between the beads that absorb moisture which lessens thermal and physical performance.

Extruded polystyrene is a closed-cell material with higher compressive strengths, R-values and moisture resistance than any grade of EPS. View the Extruded V's Expanded.

What is R-Value?

R-value is a measure of thermal resistance used frequently in the construction industry and is the standard for measuring insulations effectiveness.

What are Stella RX advantages?

Stella RX closed-cell construction gives it many advantages over expanded polystyrene such as:

- Higher R-value per thickness

- No physical or thermal loss through moisture absorption

- Higher impact resistance

- A twenty-year warranty

What are The "R-Values" of Stella RX?

- 50mm = R1.78

- 75mm = R2.67

- 100mm = R3.56

Why do some other products have much higher R-Values?

Generally, they don't. Many products falsely use the American system, not the Australian system, which has R-value ratings around 6 times greater than the Australian standard. So an R-value of R6.0 in America is around R1.0 in Australia.

Austech also uses the Australian standard temperature of 24°C, but if you use a smaller temperature, you get a greater R-value. For instance, 50mm of Stella RX has an R-value of R1.78 at 24°C but at minus 30°C this jumps to R2.22. If you are having difficulty understanding R-values, contact our technical assistants here.

Is Stella RX affected by termites?

No. Stella RX is not a food source for ants or termites but they may use it as a path to a food source. Standard termite protection processes should be used as with any other building materials.

Is Stella RX fire rated?

Stella RX has the following fire rated indices:

- Fire-rated indices as1530.3

- Ignitability 9 (0-20)

- Spread of flames 6 (0-10)

- Heat evolved 6 (0-10)

- smoke developed 8 (0-10)

What sizes and thicknesses are available?

Stella RX comes in various thicknesses, from 25mm up to 100mm. layers can be combines to reach desired R-value.

The standard board size are:

2050 x 600 with a shiplap edge on the long sides plus Stella RX 50mm is also available in 2400 x 1200.

Can i go and visit some projects that use Stella RX?

Yes, try our case studies for projects that have used our products, or contact us and we can recommend one in your area. Generally, Extruded polystyrene is placed below a layer of finishing products, like ballast or render, so you rarely get to see it.

How do I fix extruded polystyrene to my substrate?

This depends greatly on your application. When used as concrete roof insulation Extruded Polystyrene can be held in place with simple ballast, while we can provide specially designed washers for lightweight construction and high strength pins for precast insulation. Contact our technical advisors for fixing recommendations.

Environmental strategy

Extruded Polystyrene insulation is an inherently green product. Insulation is designed to limit thermal fluctuations, reducing the need for artificial temperature controls, and in turn the need for electricity and fossil fuels. Stella RX estimates that each year their range of insulation eliminates over 1 Billion tonnes of greenhouse gas emissions - equal to the annual emissions of 200 million passenger cars or two billion barrels of oil. Owens Corning doesn't just rely on their insulation to save the environment. Owens Corning's constant effort to reduce their environmental impact earned them 56th place in Newsweek's 2010 top 500 greenest American companies, ahead of American Express, Apple and Ford Motors. Owens Corning has also set targets to reduce its GHG Emissions, Energy Consumption, Particle Matter, Nitrogen Oxides, Waste to Landfill and Water Consumption.

Are you looking for technical data, and case studies? You can download them here.

Extruded polystyrene has you covered

Durability, reusability, moisture resistance, and the ability to retain R-value in the presence of water enables Stella RX XPS insulation to be used in a wide variety of building applications from roof insulation to below-grade use where the insulation will be in constant contact with moisture.

PRMA insulation is placed directly over the waterproof membrane, providing protection for the membrane and also creating a continuous thermal barrier on the roof. Stella RX is held in place with a specified ballast, usually gravel or concrete pavers.

Good insulation pays for itself

Stella RX high compressive strength means it can easily be walked on once the specified ballast has been installed. This creates an easy space for maintenance crews to access the roof, but can also help create rooftop recreation areas, adding an extra usable space to the building and increasing urban public space. Extruded Polystyrene Insulation requires no additional waterproofing and can easily cope with regular water immersion making it ideal for retro-fitting on older buildings.

Are you looking for technical data, and case studies?

You can download them here.

Email us with your project plans, so we can guide you through our collection of technical data, scientific journals and manuals.

New South Wales (Head Office)

27 Prince William Drive

Seven Hills NSW 2147

Phone: 02 9831 1623

Queensland

3/19 Moreton Bay Road

Capalaba QLD 4157

Phone: 07 3268 3066

Austech External Building Products Pty Ltd

ABN 16 058 986 511